Automatic 2000ml 3 In 1 PET Water Filling Machine

Product Details:

| Place of Origin: | Zhangjiagang, China |

| Brand Name: | FILLPACK |

| Certification: | CE/ISO9001 |

| Model Number: | CGF8-8-3 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | 11,500USD |

| Delivery Time: | 15 Working Days After Deposit |

| Payment Terms: | L/C, D/A, D/P, T/T, MoneyGram |

| Supply Ability: | 20 Sets Per Months |

|

Detail Information |

|||

| Capacity: | 3000BPH | Packaging Material: | Plastic |

|---|---|---|---|

| Bottle Volume: | 200ml-2000ml | Suitable Bottle: | PET Round Or Square Bottle |

| Core Components: | Motor, Pump, PLC, Engine | Material: | SUS304 |

| Air Pressure: | 0.4Mpa | Voltage: | 380V |

| Dimension(L*W*H): | 1800*1500*2300mm | Key Selling Points: | 3 In 1Automatic |

| Highlight: | Automatic PET Water Filling Machine,2000ml PET Water Filling Machine,2000ml automatic water bottling machine |

||

Product Description

High Efficiency CGF 8-8-3 Series Automatic 3 in 1 PET Bottle Water Washing Filling Capping Machine

![]()

- Product Features -

stably and the product quality.

Characteristic of the screwing capper as follows:

Characteristic of the screwing capper as follows:

1. The equipment is used in production of non-soda drink of hot juice or cold water packed in

polyester bottles. Washing, filling and capping are integrated in one machine.

2. The most advanced technology from Japan and Germany is employed in the design. The gravity fixed liquid surface filling is used. The filling is fast, the amount of liquid is accurately controlled and the dropping and leakage are avoided.

3. Spring cramps are used in the bottle washing process. The empty bottles can be turned over 180~ along the conveying rail. There are two times of internal and external washing, the efficiency of bottle washing is high.

4. The filling by spring type liquid lever controlling filling valve, no dripping. The liquid lever is easy to control. All

construction made of SUS304, There is no dead corner inside filling valve.

The magnetic torque is used for screw capping. The power of screw capping can be adjusted without steps. The power of the screw capping can also be fixed, and the caps will not be damaged, the capping is reliable.

5. There is electrical heating cold-heat tank enclosed in the whole system especially for keeping hot filling temp during hot juice filling. And it can also be stopping heating by easy electrical break down for cold water filling. It do not need extra steam system to work together.

6. The whole machine is controlled by PLC with touch-screen as the human-machine interface.

7. The amount of the drinks in the storage tank can be controlled automatically. The filling and capping will be stopped automatically when there is no bottle. When bottles are cramped wrongly or when caps are not available, the machine can be stopped automatically.

8. The frequency changing technology is used to adjust the operation speed sleeplessly. The production capacity can be displayed digitally and can be adjusted conveniently.

polyester bottles. Washing, filling and capping are integrated in one machine.

2. The most advanced technology from Japan and Germany is employed in the design. The gravity fixed liquid surface filling is used. The filling is fast, the amount of liquid is accurately controlled and the dropping and leakage are avoided.

3. Spring cramps are used in the bottle washing process. The empty bottles can be turned over 180~ along the conveying rail. There are two times of internal and external washing, the efficiency of bottle washing is high.

4. The filling by spring type liquid lever controlling filling valve, no dripping. The liquid lever is easy to control. All

construction made of SUS304, There is no dead corner inside filling valve.

The magnetic torque is used for screw capping. The power of screw capping can be adjusted without steps. The power of the screw capping can also be fixed, and the caps will not be damaged, the capping is reliable.

5. There is electrical heating cold-heat tank enclosed in the whole system especially for keeping hot filling temp during hot juice filling. And it can also be stopping heating by easy electrical break down for cold water filling. It do not need extra steam system to work together.

6. The whole machine is controlled by PLC with touch-screen as the human-machine interface.

7. The amount of the drinks in the storage tank can be controlled automatically. The filling and capping will be stopped automatically when there is no bottle. When bottles are cramped wrongly or when caps are not available, the machine can be stopped automatically.

8. The frequency changing technology is used to adjust the operation speed sleeplessly. The production capacity can be displayed digitally and can be adjusted conveniently.

-Technical Parameters-

|

Model

|

CGF8-8-3

|

Dimensions

|

1800*1500*2300mm

|

|

Capacity

|

2000BPH

|

Bottle Type

|

PET Bottles

|

|

Filling Range

|

200ml---2000ml

|

Cap Type

|

Plastic Screw Cap

|

|

Voltage

|

220/380V

|

Suitable For

|

Non-carbonated Water

|

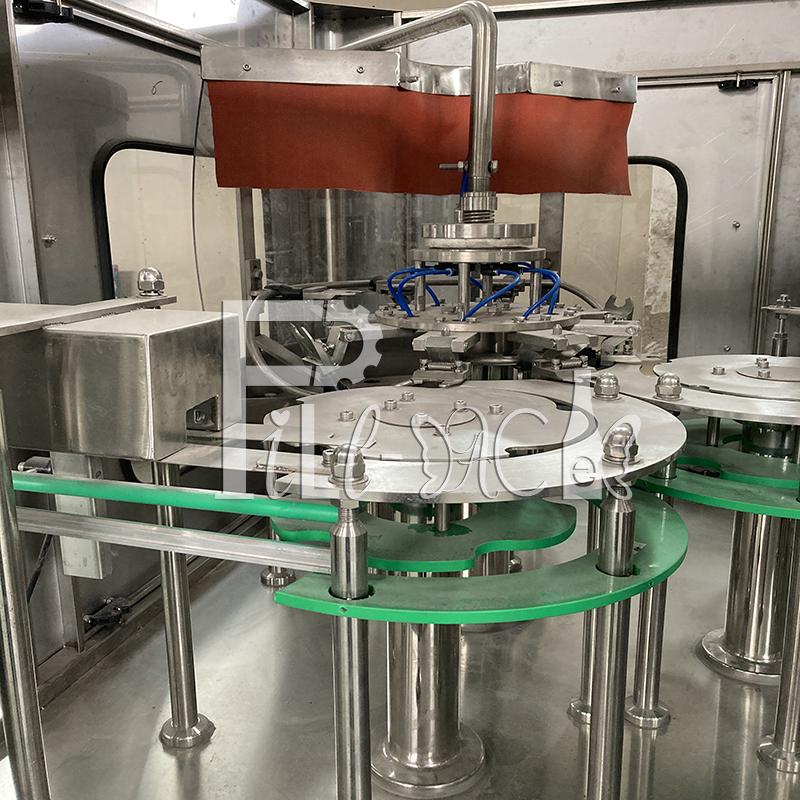

-Detailed Images-

Washing Part

1) Into bottle way is air conveyor direct connection with Bottle dial .

2) All 304 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean .

3) The gripper equipped with high-efficient spray nozzle, it can develop to any position of inwall of the bottle, and can save rinsing water.

4) Rinsing time can be guaranteed for 4 seconds.

2) All 304 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean .

3) The gripper equipped with high-efficient spray nozzle, it can develop to any position of inwall of the bottle, and can save rinsing water.

4) Rinsing time can be guaranteed for 4 seconds.

5) The supplying of rinsing water is controlled by solenoid valve.

Filling Part

1) Adopted Germanyanti-corrosion non-maintaining bearing that can reduce the pollution of filling to the environment.

2) The rotate plate is made of SUS AISI304, large flat toothed bearing.

3) The whole valve is made of 304 stainless steel.

4) The filling system has a CIP circulation system to wash the pipeline and fake-cup used for cleaning filling valve.

5) The liquid supply adopts the automatic pneumatic valve magnetic liquid-level switch to control the liquid tank automatically.

2) The rotate plate is made of SUS AISI304, large flat toothed bearing.

3) The whole valve is made of 304 stainless steel.

4) The filling system has a CIP circulation system to wash the pipeline and fake-cup used for cleaning filling valve.

5) The liquid supply adopts the automatic pneumatic valve magnetic liquid-level switch to control the liquid tank automatically.

Capping Part

1) Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

2) A bottle inlet detect switch is settled on the screwing capper.

3) No bottle no capping

4) Automatic stop when lack of bottle

5) The motivation of the screwing capper is derived from the driven system in the framework and passed by gear.

3) No bottle no capping

4) Automatic stop when lack of bottle

5) The motivation of the screwing capper is derived from the driven system in the framework and passed by gear.

Want to Know more details about this product